We propose a fully ready-made device that automatizes various manufacturing lines with using our robotic technologies developed through their introduction to a wide range of industries including automobile parts, foods, household equipment and railways. Many devices have been produced which can be referred to as “Patented” and/or “First in Industry”. We are extending the boundary of fields in which our presence can be felt through our technological capabilities that lead the industry.

We propose a fully ready-made device that automatizes various manufacturing lines with using our robotic technologies developed through their introduction to a wide range of industries including automobile parts, foods, household equipment and railways. Many devices have been produced which can be referred to as “Patented” and/or “First in Industry”. We are extending the boundary of fields in which our presence can be felt through our technological capabilities that lead the industry.

Technology Structure

Various Types of Specialized Machine Automation Technologies

Business Outline

| Business Areas | Domestic & International |

| Share & Original Technologies | Patented Technology: Automatic Inspection Device for Screw Hole of Parts Firs in Industry: Automatic Conveyance System for Train Cars |

Proposed Case

Saving of workload, stabilization of product quality and speeding-up of manufacturing processes. We satisfy your needs of cost reduction with our rich experiences and know-hows.

3D Random Picking System

Product Outline

This is a robot system equipped with a 3D vision system. Under the 3D recognition of randomly arranged parts, the robot is able to produce a picking motion with automatically imaging the trajectory of such motion. We have succeeded in handling a part which position has not been fixed. All previous robot systems have failed to realize this technology.

This is a robot system equipped with a 3D vision system. Under the 3D recognition of randomly arranged parts, the robot is able to produce a picking motion with automatically imaging the trajectory of such motion. We have succeeded in handling a part which position has not been fixed. All previous robot systems have failed to realize this technology.

Challenges before Product Development

The previous robot systems have not been able to pick a part randomly arranged in the box or produce equivalent motions, although they could handle one which position has been fixed. Also, while such systems became able to recognize the position of a part with using the 3D vision system, it took time to launch an on-site project because the robot teaching for not interfering in the box consumed vast amount of hours.

Points in Product Development

Building a perfectly teaching-less random picking system in cooperation with MUJIN INC., a robot controller manufacturer.

- Completing the robot teaching only by configuring the settings in an offline simulation

- MUJIN controller automatically calculates the trajectory of a motion, etc. from the posture of the work in its hand; No need of more than one teaching pattern, etc.

Random Picking Device Equipped with 3D Camera

Random Picking within Pallet

Random Picking within Pallet

Able to pick a work randomly arranged in the box by recognizing it with a 3D camera

Conveyor Random Picking

Conveyor Random Picking

Capable of picking a work randomly placed and positioned while recognizing it with a 3D camera and following the motion of a conveyor

Grinder Robot System

Product Outline

This is a system in which the robot with a 3D sensor and a grinder automatically recognizes the figure of a huge bulb used for nuclear generation facilities, etc. and engages in surface grinding processes. This system enables the robot to do the processing with tracking an appropriate trajectory against the intricately shaped surface.

This is a system in which the robot with a 3D sensor and a grinder automatically recognizes the figure of a huge bulb used for nuclear generation facilities, etc. and engages in surface grinding processes. This system enables the robot to do the processing with tracking an appropriate trajectory against the intricately shaped surface.

Challenges before Product Development

The surface processing of a large-sized intricately shaped bulb used to be the crude processing manually and thoroughly done by workers with a grinder, being a very exhausting work for them. It took much time to achieve the automation of the relevant work because its variation in size made it difficult to recognize the object’s figure with a fixed camera from above and also because the teaching enabling the robot to do processing along a curved surface had a high level of difficulty.

Points in Product Development

Synthesizing respective images based on the coordinate of a robot with a laser scanner has made it possible for the robot to recognize the curved surface of an object in a large-sized work.

- A laser scanner and a grinder are switched to each other with an automatic tool changer.

- The point group data retrieved with a scanner has enabled the settings of the operating position and the speed of a robot, making the complicated imitative robot teaching unnecessary.

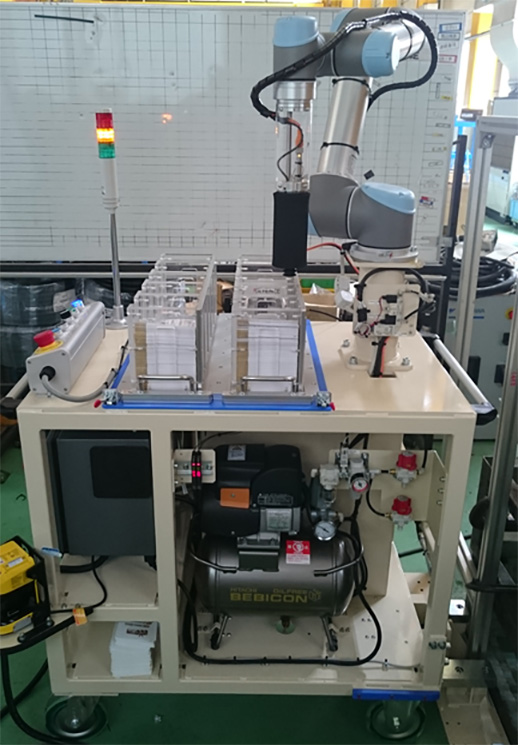

Universal Robot

Product Outline

The universal robot is a next-generation industrial one developed for the purpose of cooperative works with human. This is a small, lightweight and directly teachable robot so that anybody can do its teaching without difficulty.

The universal robot is a next-generation industrial one developed for the purpose of cooperative works with human. This is a small, lightweight and directly teachable robot so that anybody can do its teaching without difficulty.

Features

- A single person can move this robot because its main body is a lightweight one.

- Capable of doing cooperative works with human

- Able to set its power, speed and range of operation with using respective six shafts

- Directly teachable

- Possible to be installed on the floor, ceiling, wall and slope ground

- Able to be operated in a narrow space

- Easy to be programmed

- Capable of controlling the power by itself

- Equipped with a safety shutdown system in case of a collision with human

- Maintenance-free

- 100V single-phase electric power source (with an earth wire)

Automatic Conveyance System for Train Cars

Product Outline

This is a device that has enabled the conveyance of a train car within the factory for its maintenance. The conveyance system in cooperation with tracks build within the factory moves huge train cars. This is our original system firstly developed in the industry.

This is a device that has enabled the conveyance of a train car within the factory for its maintenance. The conveyance system in cooperation with tracks build within the factory moves huge train cars. This is our original system firstly developed in the industry.

Challenges before Product Development

- To reduce the burden of workers through an automatic conveyance system who used to convey train cars by pushing them by their own hands (partially with a gasoline-powered trolley)

Points in Product Development

Automatic conveyance system using the control system

- Smooth conveyance to the next process

- Efficient use of spaces in the maintenance factory through the installation of the conveyance system in a bit

- Handling many types of train cars through the adjustment in the number of system units

Automatic Cutting Machine for Thin Materials (Commonly Called as Clipper)

Product Outline

This machine cuts 0.1 mm-thick materials in a precise manner. Intended materials include a variety of ones such as paper, film and heat insulating materials. It can deal with materials of all sizes from small to large.

This machine cuts 0.1 mm-thick materials in a precise manner. Intended materials include a variety of ones such as paper, film and heat insulating materials. It can deal with materials of all sizes from small to large.

Challenges before Product Development

- Precise cutting of extremely thin materials

- Speeding-up of works

- Work-saving

Points in Product Development

Full automation of the cutting work of thin materials via robotic control

- Realizing the precise cutting of many types of materials from small to large through prior programming

- Automating a series of processes from cutting to those before and after it (the conveyance of materials, picking, etc.); Improving working efficiency (speeding-up)

Automatic Inspection Device for Screw Hole of Parts

Product Outline

This device automatically inspects the screw holes of parts and products that have been already processed. This is a patented technology that has substantially improved the inspection capability and work efficiency by its robotic technologies. Further, through the combination of the inspection device for screw holes and peripheral equipment, this device has enable the establishment of a series of systems for the inspection of screw holes which has been considerably improved in terms of labor-saving.

This device automatically inspects the screw holes of parts and products that have been already processed. This is a patented technology that has substantially improved the inspection capability and work efficiency by its robotic technologies. Further, through the combination of the inspection device for screw holes and peripheral equipment, this device has enable the establishment of a series of systems for the inspection of screw holes which has been considerably improved in terms of labor-saving.

【List of Functions】

- Simultaneously measuring the torque and the depth of a screw hole

- Automatically controlling the rate of rotation and torque according to the screw process

- Identifying the problems including any trouble in the engaging status of screws, the absence of a screw and the existence of an obstacle

- Detecting abnormal torque during a screwing process

- Determining the depth of a screw

- Correcting the misalignment of a position (±0.25 mm) via a radial floating mechanism

- Automatically exchanging a gauge through the combination with tool holders (optional)

- Dealing with an angled screw hole by adding the rotation mechanism to the fixture table (optional)

Challenges before Product Development

- Not a few working hours and headcount were required to provide sound product quality which had not been able to be achieved through an inspection or a pass-fail judgement by the hands of human.

Points in Product Development

Full automation of the inspection work of a screw hole through robot control

- Enabling a single device to inspect many types of products by prior programming

- Achieving the sound quality of an inspection

- Handling a huge amount of inspections

- Automating a series of processes from the inspection of screw holes to those before and after it; Saving labors and improving work efficiency (speeding-up)