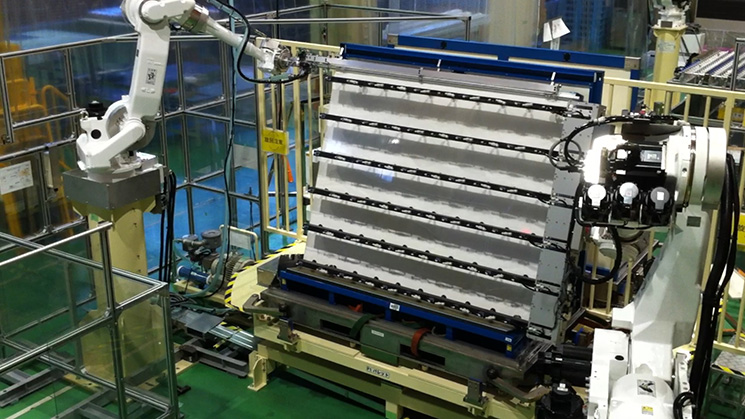

Development and Manufacturing of Transport Systems

for Ultra-Thin LCD Panels Just 0.3–0.7 mm Thick

At Sanmei Kikou, we develop and manufacture transport systems for ultra-thin LCD panels with a thickness of just 0.3 to 0.7 millimeters. These panels are extremely delicate and prone to damage such as scratches or cracks, requiring advanced precision engineering.

Our transport systems are designed to safely and accurately convey these panels while minimizing the risk of damage throughout the process. The LCD panels supported by this technology eventually become essential components of products like televisions, smartphones, and tablets that are integral to modern life.

Sanmei Kikou’s technology goes beyond simple transportation—it serves as a foundation that supports the digital society in many aspects. We contribute to the continuous advancement of modern technology through our innovative transport solutions.

Custom-made support

At Sanmei Kikou, we go beyond standardized products to offer fully customized designs and manufacturing based on client requests. We provide optimal solutions tailored to each industry and application.

Commitment to quality

We apply strict quality control to each product, delivering reliable and durable systems. Our commitment to high quality standards ensures products that can be used with confidence over the long term.

Quick and flexible response

From development to delivery, we strive for quick and flexible responses in every process. We adapt promptly to customer requests and market changes to achieve the best possible outcomes.

Environmental Considerations

We design and manufacture with a focus on minimizing environmental impact, contributing to a sustainable society. We promote energy-efficient systems and waste-reducing production methods.

QCD and Carbon Neutrality

At Sanmei, we pursue excellence in QCD—Quality, Cost, and Delivery—while actively promoting carbon neutrality. We aim to reduce environmental impact and contribute to a sustainable future by optimizing production efficiency and introducing energy-saving technologies.