Virtual Robot Solution Center

At the VRSC (Virtual Robot Solution Center), we utilize the VRSS (Virtual Robot Solution System) to project and verify robot system operations on large screens or through VR goggles using 3D simulation. This facility enables the recreation of your factory environment in a life-size virtual space, allowing for in-depth examination of potential system issues before implementation.

With this approach, you can intuitively identify factors that are often overlooked in blueprints, such as structural strength, interference, operability, and maintainability. In addition, the center includes an experimental area where processing conditions that cannot be confirmed through simulation alone can be tested and validated.

Our team of experienced professionals will work closely with you to support the development of an optimal system tailored to your needs.

Review Your System in VR

At our company, we provide a comprehensive environment for system evaluation using factory automation (FA) simulators, featuring a 200-inch large monitor and VR goggles. This setup allows you to realistically experience the actual scale and layout of equipment within a virtual space.

We also offer an extensive library of peripheral devices, including the latest robots, enabling rapid creation and assessment of system operation scenarios. Furthermore, by using a 3D scanner to capture your factory in advance, we can accurately place equipment within the actual installation space in the simulation for detailed verification.

Advance Software Verification

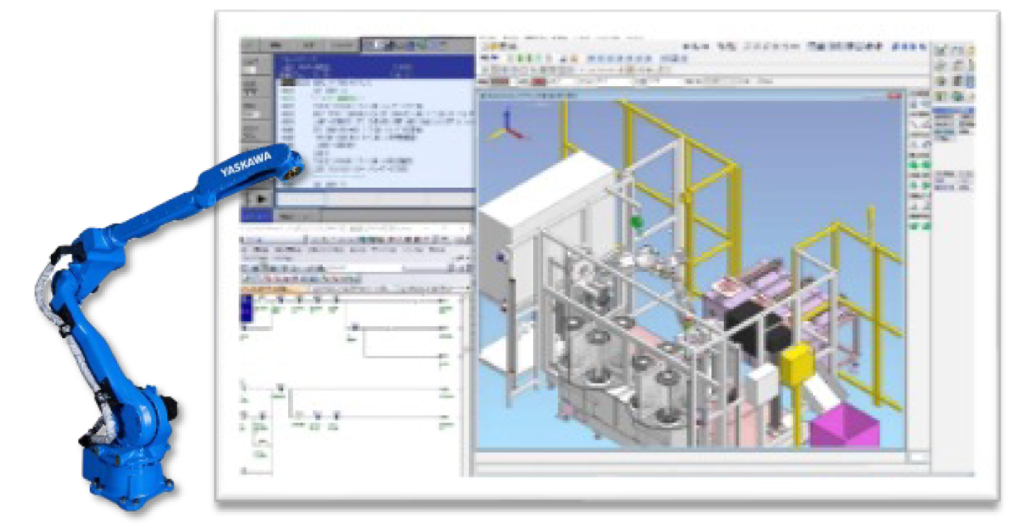

By connecting PLCs and robot simulators, we perform offline debugging to digitally verify system concepts in advance. This enables not only standard operation checks but also pre-verification of abnormal recovery procedures and maintenance tasks, all before actual system construction.

Building the software beforehand allows for vertical startup of the system, enabling rapid commencement of production. We accurately reflect customer requirements to deliver an optimized system.

Advance Mechanical Verification

Our mechanical pre-verification process utilizes VR to allow multiple users to intuitively and efficiently check numerous aspects that are difficult to confirm from blueprints. It enables full-scale visualization of elements such as mechanical interferences, safety fences, doors, and pathways, allowing for more concrete validation.

Through VR, users can experience the actual scale of equipment, gaining a more precise understanding of dimensions that are hard to grasp on drawings. Furthermore, by simulating line takt time, human motion flow, and handling uncertainty based on physical properties, we can pre-evaluate operation rates with high accuracy.

For aspects that cannot be verified through simulation alone, we provide real-world testing in our adjacent demonstration area to ensure a more reliable system design.

Consulting & Feasibility Study (FS) Support

We offer comprehensive support, from identifying customer challenges to proposing automation solutions and defining detailed specifications. Our services include feasibility studies for robot implementation—covering workflow analysis, robot system planning, and cost-effectiveness evaluation.