Achieving Automation of Aluminum Die-Casting Production Lines

Using the Latest Industrial Robot Technologies

Sanmei Kikou leverages the latest industrial robot technologies to automate aluminum die-casting production lines. Our comprehensive system covers every stage of the process—including ingot feeding, pouring systems, mold release agent spraying, product extraction, gate cutting, deburring, and visual inspection—ensuring enhanced productivity and stabilized product quality to meet a wide range of customer needs.

Our aluminum die-casting automation systems are deployed not only across Japan but also globally in countries such as South Korea, China, India, Indonesia, the United States, Mexico, and Thailand. Among these, our robotic mold release agent sprayer has received high acclaim for its use of nozzles that externally mix the release agent with air, minimizing clogging and ensuring excellent maintainability.

We also offer a diverse lineup of solutions tailored to customer needs, including robotic hands for product extraction, insert equipment for metal embeds, automatic gate cutting systems, and runner breaking equipment. These devices are designed in alignment with product shapes and process flows and can be seamlessly integrated with upstream and peripheral equipment.

Our technology also plays a crucial role in manufacturing essential components of modern society such as EV battery cases, engines, and gear reducers. Given the high demands for safety and precision in these products, our automated lines have earned strong trust and recognition throughout the industry.

One of our key strengths lies in our fully integrated in-house production system, from design to manufacturing, enabling us to deliver completely customized solutions tailored to each client’s requirements. We also support upgrades and automation of existing production lines, ensuring optimal solutions that precisely reflect on-site needs.

Custom-made support

At Sanmei Kikou, we go beyond standardized products to offer fully customized designs and manufacturing based on client requests. We provide optimal solutions tailored to each industry and application.

Commitment to quality

We apply strict quality control to each product, delivering reliable and durable systems. Our commitment to high quality standards ensures products that can be used with confidence over the long term.

Quick and flexible response

From development to delivery, we strive for quick and flexible responses in every process. We adapt promptly to customer requests and market changes to achieve the best possible outcomes.

Environmental Considerations

We design and manufacture with a focus on minimizing environmental impact, contributing to a sustainable society. We promote energy-efficient systems and waste-reducing production methods.

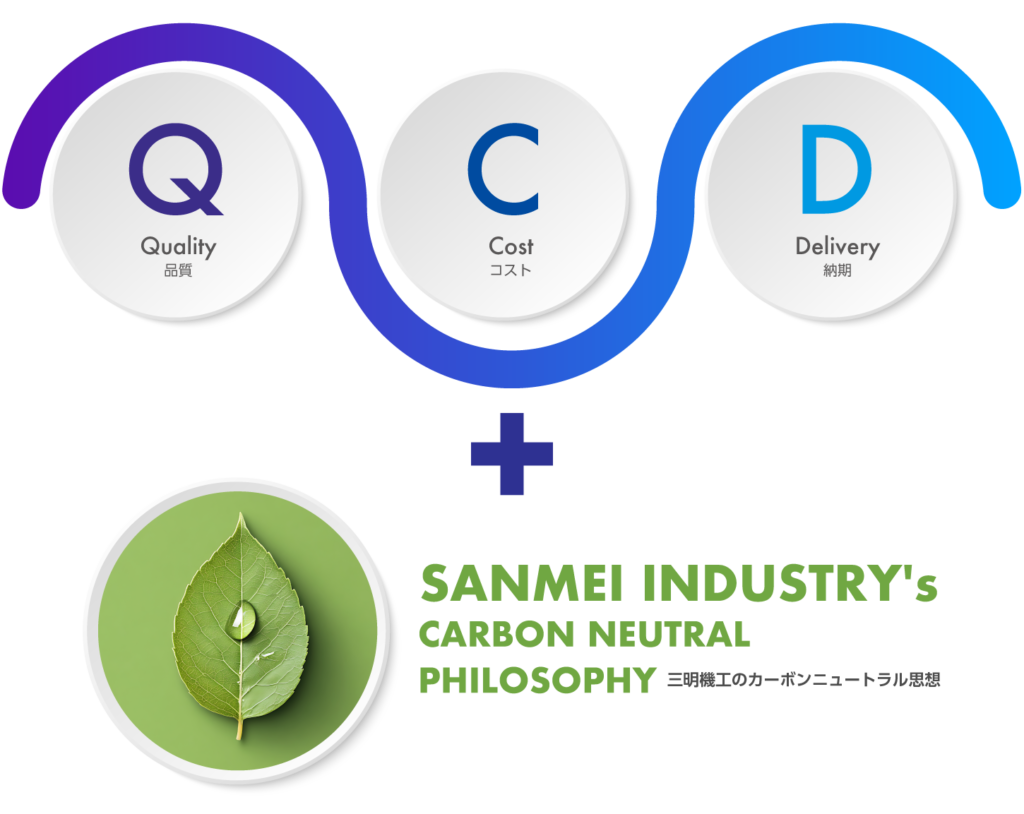

QCD and Carbon Neutrality

At Sanmei, we pursue excellence in QCD—Quality, Cost, and Delivery—while actively promoting carbon neutrality. We aim to reduce environmental impact and contribute to a sustainable future by optimizing production efficiency and introducing energy-saving technologies.